Figuring with nanometer precision

by Plasma CVM

(Chemical Vaporization Machining)

Increased etching rate through the application of atmospheric-pressure plasma

Damage free because of the removal by chemical vaporization

There is no erosion of electrodes and reproducibility and stability are good

Since it is a non-contact process, there is no impact from vibration or thermal deformation → removes copy principle

Si, SiO2, SiC, Si3N4, and diamond, among others, can be etched

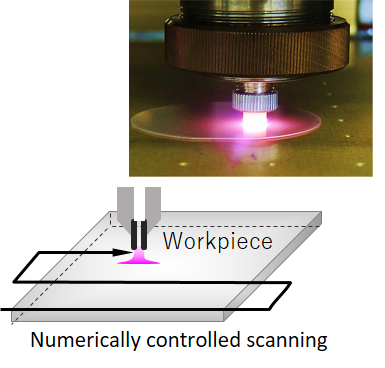

Schematic of Plasma CVM

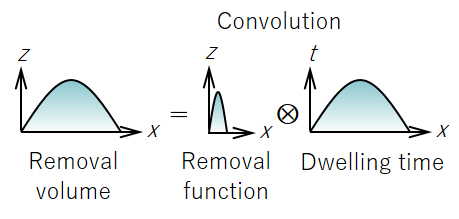

<Process flow of Numerically Controlled Plasma CVM (NC-PCVM) >

step1Shape measuring

step2Simulation

step3Shape correction

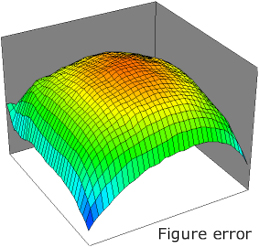

step4Shape accuracy wit nanometer order

Based on the numerically controlled scanning of localized plasma, the shape is modified and the target shape can be obtained deterministically with nano-precision without using a trial and error approach.

Thickness distribution correction of quartz crystal wafer