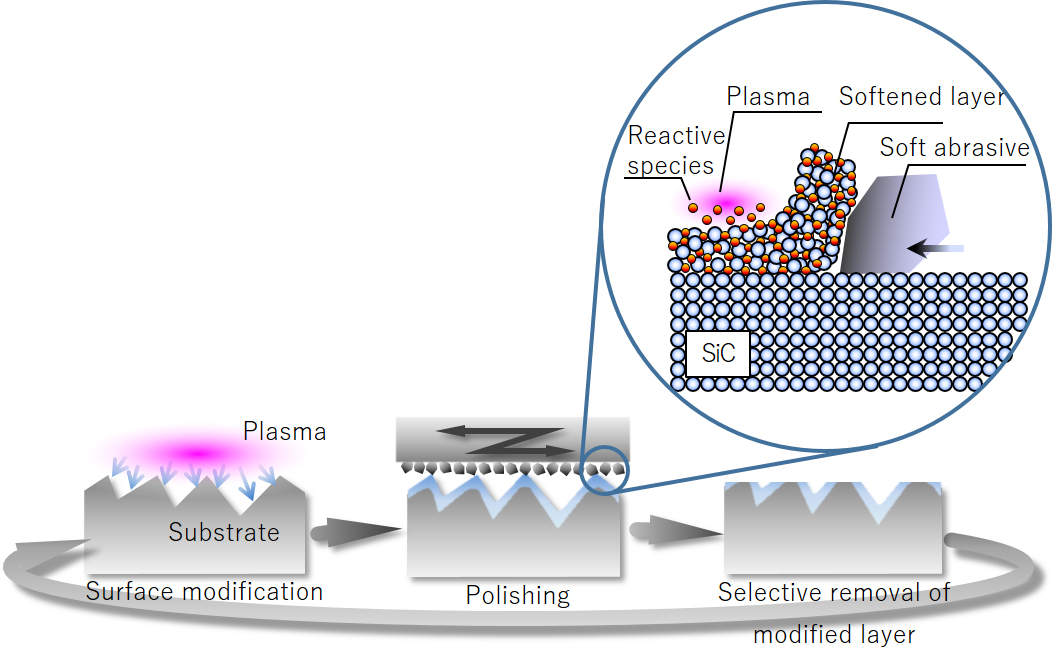

Finishing with out damage【JP PAT 5614677】

by Plasma Assisted Polishing (PAP)

Surface of hard/brittle materials is softened by plasma irradiation, and the modified layer is removed by polishing with soft abrasive grains, making the process relatively damage free.

There are few expendables, which keeps the manufacturing cost low.

Since this is a dry-etching process, etch pitting does not occur.

In comparison with chemical mechanical planarization (CMP), the apparatus is simply structured.

SiC, GaN, AIN, diamond, and sapphire, among others, can be polished.

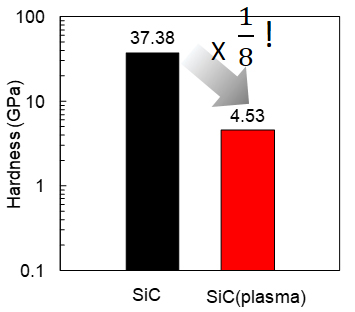

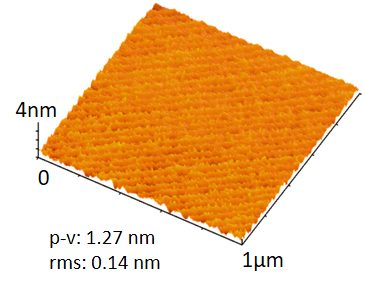

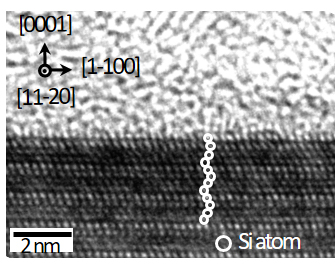

4H-SiC (0001)

Hardness before and after plasma irradiation

Atomically smooth surface

Damage-free surface

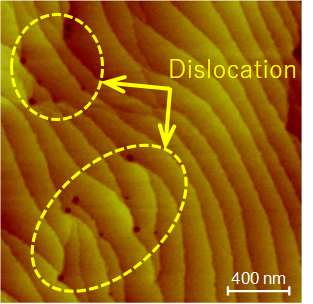

GaN (0001)

3.65 nm p-v, 0.28 nm rms

Before polishing

4.04 nm p-v, 0.43 nm rms

Processed by CMP (Silica slurry)

0.67 nm p-v, 0.08 nm rms

Processed by PAP